Flashfashion

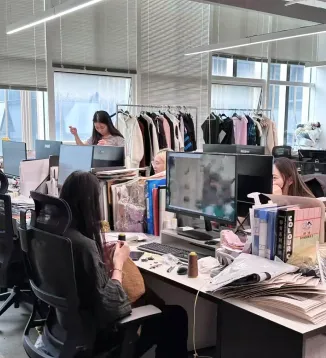

manufacturer. The factory covers an area of 3,000 square meters, has 68 employees and a monthly production capacity of over 30,000 pieces. The main services are brand OEM and personalized sample customization, without the restrictions of MOQ, and it has a strong comprehensive clothing process production capacity. The main cooperative countries are mainly from Europe, America, Southeast Asia and the Middle East. The factory has high-quality service capabilities and a strong technical team, mainly serving designers and brand companies. Grow together with partners and create the future.

- Impeccable Finish

- Impeccable Finish

- Impeccable Finish

8 Sectoral Collaboration

How How they do their jobs well

I’ve been in the industry for 15 years and have been exposed to many more customers.For their own position work, help customers to make products if the price, the product has been confirmed. The most important thing is to do a good job in every detail, help customers to monitor the quality of production, and the whole process of service, so that both sides can be good to cooperate.

Management of a factory will have many, many things, often have to think about to headache.1. The most important thing is that if there is a problem, it must be solved immediately, this is my idea of doing this position, 2 to ensure that each order in accordance with the time of delivery, so that customers can rest assured. There may be problems with the fabric, the product in addition to errors, or a lot of time for orders during peak times. There must be many problems in running a factory.

strive for excellence and meticulousness in drawingevery single pattern. With professional skills, linterpret design concepts precisely, laying a solidfoundation for creating perfect garments.

What we do to solve the common problems of our customers

01 What about employees' birthdays?

Every month, we dedicate one employee’s birthday and everyone participates. It makes our work more fun. For example, we’ll chat together in the conference room and have a fruit dinner party.

02 Production order staff found that the sample shrinkage rate is problematic, how to solve the problem?

Firstly check the fabric for correct shrinkage and recalculate the size. Expedite the re-sample to be completed in the time requested by the customer.

03 How is the production sequence arranged when there are particularly large orders?

There are special production meetings every week to execute the time plan of production according to the customer’s required time.

04 The sample model is not up to standard, how can I fix it?

Individual staffing and time to rework and expedite production.

05 Customers need personalised fabrics or accessories, how do factories source fabrics?

According to the design drawings given by the customer and the customer’s brand concept. Firstly, we provide customers with a variety of options, and finally customers determine the fabrics and accessories according to the information provided by the sales staff.

06 The production completion time requested by the customer is very short, far below the normal production time, and the customer has already placed an order. How can the factory arrange this?

First of all, we discuss the time programme with the customer first, while the factory actively cooperates to help the customer to shorten the time.

07 How to pack and ship the product after it has been manufactured?

Immediately into the quality control and packaging workshop. Commitment to the quality of the product threads and ironing of the clothes to pass, as well as packaging neat and beautiful.

08 Customers come to China to visit the factory, how the factory is arranged?

Firstly the business confirms the time to the client and then arranges the hotel and transport.